2025 Powder Particle Metering Equipment Purchase Guide

Looking for the right powder particle metering equipment in 2025? This guide breaks down the top systems—multi-component suction weighing scales, incremental weighing machines, additive dosing units, and precision batching systems—to help you choose the perfect solution for accurate, efficient, and automated production.

Choosing the right powder particle metering equipment in 2025 is no longer just about “getting the job done.” Precision, automation, traceability, and production efficiency have become the pillars of modern manufacturing—from plastics and chemicals to food additives and battery materials. If you’re planning to upgrade (or build) a metering system this year, this guide will walk you through the essentials with a fresh, practical perspective.

Whether you're weighing micro-additives or managing multi-component batches, the right tools can dramatically improve consistency and reduce costly human error. Below, we explore the four major categories shaping today’s powder-metering landscape—along with insights to help you make a smart purchase.

1. Multi-Component Suction Weighing Scale: Best for High-Efficiency, Centralized Feeding

If your production line handles several powders or granules at once, a Multi-Component Suction Weighing Scale is a genuine game-changer.

This system uses negative-pressure conveying to pull materials from silos, automatically weigh them, and send them to the next processing stage—all with minimal manual intervention. Its biggest advantage? You get fast, dust-free material transfer combined with accurate weighing for multiple ingredients in a single process.

What to look for when purchasing:

Stable vacuum conveying with no cross-contamination

High-precision load cells

Automated recipe control

Real-time data and batch traceability

Ease of cleaning and maintenance

A well-designed multi-component system can boost both throughput and material accuracy, especially in PVC compounding, masterbatch production, chemical powder mixing, and more.

2. Powder and Granule Incremental Weighing Scale: When Accuracy Matters Most

Some production lines require accuracy that borders on obsession. For those cases, a Powder and Granule Incremental Weighing Scale stands out.

Instead of weighing bulk ingredients in one go, this machine feeds powders incrementally—tiny portions at a time—until the exact preset value is reached. This design dramatically improves precision and is ideal for high-value or reactive materials where even minor deviations can cause major performance issues.

Best suited for:

Battery electrode powders

Chemical catalysts

High-value pigments

Flavoring or pharmaceutical pre-mixes

Key buying considerations:

Micro-feeding stability

Repeatability under continuous operation

Compatibility with both fine powders and heavier granules

Control system precision and recipe flexibility

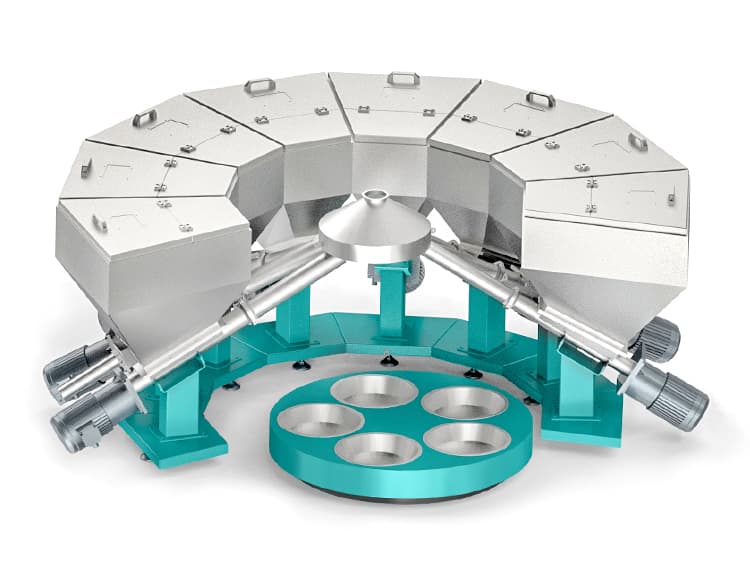

3. Additives Automatic Weighing Machine: Consistency Without Guesswork

Additives may represent only a small percentage of your formula—but they often determine product quality. An Additives Automatic Weighing Machine ensures those small-dose materials are added accurately and consistently.

These machines typically integrate multiple weighing hoppers, each configured for a specific additive. Automated gates and conveyors then deliver materials according to your preset recipes.

You’ll benefit the most if your operation requires:

Several micro-additives per batch

Traceable, repeatable dosing

Reduced labor and fewer manual measuring errors

Seamless integration with mixers or extruders

This category is especially popular in plastics processing, food mixes, chemical additives, and masterbatch factories.

4. Precision Metering Automatic Batching Machine: Full-Process Control for Modern Factories

If your goal is to automate an entire batching workflow—not just isolated weighing steps—a Precision Metering Automatic Batching Machine is the all-in-one solution.

Think of it as your factory’s “central brain.” It manages raw-material feeding, weighing, batching, data recording, recipe control, and communication with upstream and downstream equipment. When paired with modern PLC and industrial-IoT systems, these batching machines deliver the level of automation global manufacturers now expect.

Why companies choose this solution:

Maximum batching accuracy

Fully-automated material handling

Dramatic labor reduction

Batch-to-batch consistency

Data storage for audits and quality control

If you're aiming for smart-factory standards in 2025, this is the direction to go.

How to Choose the Right Metering Equipment in 2025

When evaluating your options, keep these practical questions in mind:

What material characteristics are you handling?

Flowability, density, volatility, and moisture all affect machine choice.

What level of precision is required?

±0.5% vs. ±0.05% leads you to very different categories.

Do you need full automation or partial upgrades?

You may not need a full batching system—sometimes upgrading the additive weighing module is enough.

What is your batch size and production frequency?

High throughput favors suction weighing; ultra-high accuracy favors incremental micro-feeding.

Does the equipment integrate well with your existing line?

Good PLC communication and an intuitive recipe system save countless headaches down the road.

For a deeper look at different models and configurations, you can explore solutions like Audop Metering Equipment, which cover multi-component weighing, additive dosing modules, and full automatic batching systems.

Final Thoughts: 2025 Is the Year of Smarter Metering

As factories push toward higher efficiency and tighter quality control, investing in modern metering systems is no longer optional—it’s a competitive advantage.

From multi-component vacuum weighing setups to fine-precision incremental feeders, each type of system brings unique strengths. The right choice depends on your production scale, material characteristics, and the accuracy your formula demands.

If you need reference designs or want to compare system options, check out Audop Metering Equipment for practical examples used in real manufacturing environments.